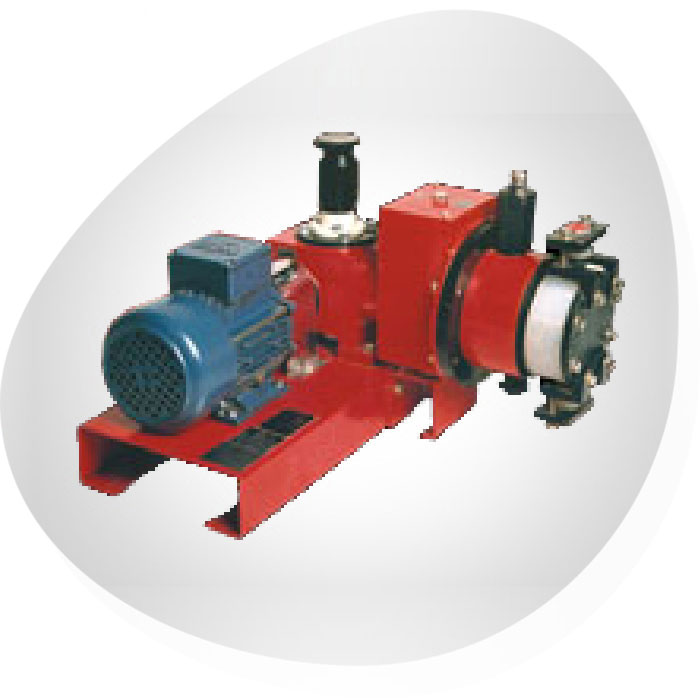

Hydraulic Diaphragm Pump

Overview

- Performance conforms to API 675.

- Glandless design and entirely Leak Proof operation.

- Integrated Pressure Relief Valve.

- Diaphragm is always balanced between the pressure exerted by the hydraulic oil and liquid to be dosed. Longer Diaphragm Life.

- Automatic air bleeding from the hydraulic oil ensures better metering accuracy.

- Manual stroke adjustment by eccentric.

Features

Hydraulically Actuated Diaphragm Type Chemical Injection Pump Installed By Us At PD Oman